Separators - Understanding what each of them do

In Various industries, managing and treating wastewater is a crucial aspect of maintaining environmental sustainability.

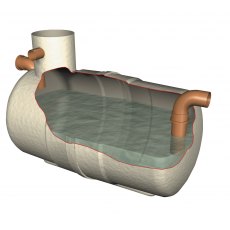

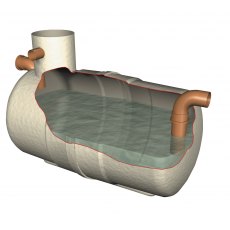

Full Retention Separators

What are Full Retention Separators?

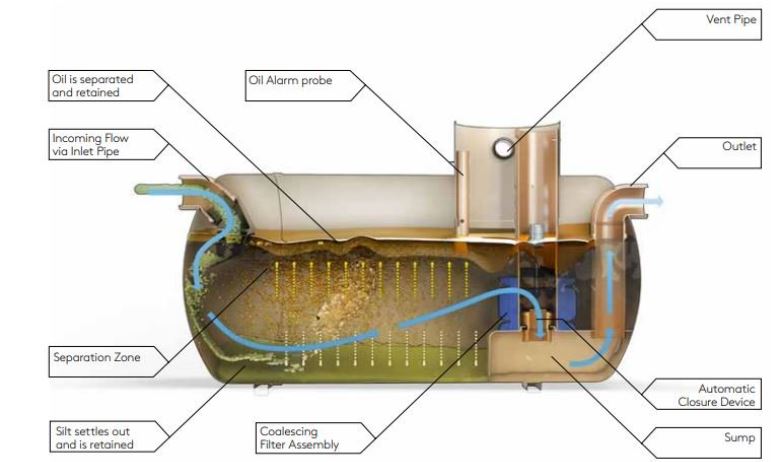

Full retention separators, also known as oil-water separators, are designed to treat the full flow (run off or spills) that can be delivered by the drainage system, which is normally equivalent to the flow generated by a rainfall intensity of 65 mm/hr. On larger sites, some short term flooding may be an acceptable means of limiting the flow rate and hence the size of full retention systems. And when you need to protect a nearby waterway, or an area that’s environmentally fragile, an oil alarm system will give you added peace of mind

On large sites, some short term flooding may be an acceptable means of limiting the flow rate and hence the size of full retention systems.

Previously known as Interceptors, where they had 3 chambers, separators are now a single pot with coalescent filters. Our separators will prevent your oil spills contaminating watercourses and groundwater.

Applications

- Industrial facilities - such as manufacturing plants, refineries, and automotive workshops, where large volumes of wastewater containing oils, greases, and chemicals are generated.

- Commercial Properties - Shopping malls, parking lots, airports, and other commercial properties often employ full retention separators to manage the stormwater run-off from large paved areas.

- Transportation Infrastructure - Installed in transportation infrastructure, such as highways, roads, and railways, to treat run off from these surfaces.

- Construction Sites

The Dos and Don'ts of Full Retention Separator Use

Dos:

Regular Maintenance

Schedule maintenance to ensure the efficient operation of the full retention separator. This includes inspections, cleaning, and servicing as recommended by the manufacturer.

Proper Installation

Ensure that the separator is correctly installed according to the manufacturer's guidelines and local regulations. This includes proper positioning, connection to the drainage system, and adequate provision for access and maintenance.

Training and Awareness

Provide training to personnel responsible for operating and maintaining the separator. Raise awareness about the importance of proper use and adherence to safety protocols.

Don'ts:

Discharge Unauthorised Substances

Do not discharge any substances into the separator that are not approved by local regulations. This includes chemicals, solvents, or hazardous materials that may compromise the effectiveness of the separator or pose a risk to the environment.

Neglect Maintenance

Avoid neglecting the regular maintenance and inspection of the separator. Neglecting maintenance can lead to reduced efficiency, increased risk of pollutant bypass, and potential non-compliance with regulatory requirements.

Modify the Separator

Do not modify the separator without consulting the manufacturer or a qualified professional. Modifications can affect the performance, warrantee, and safety of the unit.

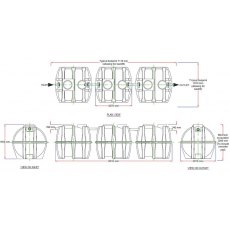

Our range of Full Retention Separators range from a drainage area of 170M² to 2780M², however larger units can be quoted for, so please contact us if a larger size is required.

(£1,405.20 inc VAT)

(£2,625.60 inc VAT)

(£2,274.00 inc VAT)

(£4,124.40 inc VAT)

Forecourt Separators

What are Forecourt Separators?

Specialised wastewater treatment systems designed to intercept and remove oil, fuel, sediment, and other pollutants from the run-off generated on forecourts. Forecourts refer to the areas surrounding fuel dispensing pumps, car wash facilities, and maintenance areas within fuelling stations or vehicle service centres.

The primary purpose of forecourt separators is to protect the environment by preventing harmful substances from entering water bodies and the drainage system. By effectively separating and treating pollutants, these separators ensure compliance with environmental regulations and promote sustainable practices in the fuelling and vehicle maintenance industry.

Applications

- Fuelling Stations - to treat the run-off generated from fuel spills, leaks, and vehicle maintenance activities, preventing oil and fuel from entering stormwater drains and contaminating water sources.

- Car Washing Facilities - producing a significant amount of contaminated run-off containing detergents, oils, and sediments.

- Vehicle Maintenance Areas - forecourt separators are installed to capture and treat wastewater from activities such as engine washing, parts cleaning, and fluid changes.

The Dos and Don'ts of Forecourt Separator Use

Dos:

Regular Maintenance

Conduct routine inspections and maintenance to ensure proper functioning of the separator. This includes cleaning accumulated sediment and regularly emptying the separator.

Compliance with Regulations

Adhere to local environmental regulations and guidelines regarding the installation, operation, and maintenance of forecourt separators.

Proper Disposal

Dispose of captured pollutants, such as oil and sediment, in accordance with local regulations and guidelines.

Don'ts:

Discharge Unauthorised Substances

Like the Full retention separators, avoid introducing prohibited substances, chemicals, or hazardous materials into the forecourt separator.

Neglect Maintenance

Neglecting regular maintenance can lead to reduced efficiency and potential system failure, comprising pollutant removal effectiveness.

Bypass the Separator

Never bypass the forecourt separator or divert wastewater directly into the drainage system without treatment.

Vehicle Washdown Separators

What is a Vehicle Wash Down Separators?

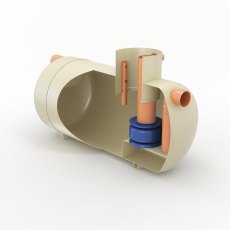

Vehicle wash down separators, also known as wash bay interceptors or wash water reclaimers, are essential components of vehicle wash facilities. These separators are designed to capture and treat the wash water run-off, ensuring that pollutants are effectively removed before the water is discharged or recycled. As contaminated water passes through the separation chamber, it is retained long enough to allow solids to sink to the bottom of the unit, at which point the water is then able to discharge safely. By removing oils, detergents, and sediments, these separators help maintain water quality, promote environmental sustainability, and comply with local regulations.

Applications

- Car wash Facilities

- Vehicle Service Centres

The Dos and Don'ts of Vehicle Wash Down Separator Use

Dos:

Regular Maintenance

Inspect and maintain routinely to ensure the optimal performance of the separator. This includes cleaning accumulated sediment, checking for any blockages, and maintaining proper water flow.

Proper Disposal or Recycling

Dispose of the captured pollutants, such as oils and sediments, in accordance with local regulations and guidelines. Alternatively, consider recycling options for treated wash water if feasible.

Compliance with Regulations

Adhere to local environmental regulations and guidelines regarding the installation, operation, and maintenance of the vehicle wash down separators.

Don'ts:

Discharge Unauthorised Substances

Avoid introducing prohibited substances, chemicals, or hazardous materials into the wash down separator.

Neglect Maintenance

Neglecting regular maintenance can lead to reduced efficiency and potential system failure, compromising pollutant removal effectiveness.

Bypass the Separator

Never bypass the vehicle wash down separator or divert wash water directly into the drainage system without proper treatment.

Bypass Separator

What are Bypass Separators?

A bypass separator is a wastewater treatment device designed to remove pollutants and sediments from wastewater before it enters a drainage system or is discharged into the environment. It consists of a series of compartments or chambers that allow different stages of separation to occur, ensuring the removal of harmful substances.

Bypass separators fully treat all flows, for the area served, generated by rainfall. Higher flows above the agreed rate are allowed to bypass the separator. These separators are used when it is considered an acceptable risk not to provide full treatment for high flows

Applications

- Car Parks and Roadways

- Fuelling Stations

- Industrial Sites

- Construction Sites

The Dos and Don'ts of a Bypass Separator Usage

Dos:

Proper Sizing

Ensure the bypass separator is properly sized and designed to handle the expected flow rates and pollutants specific to the application. Consult with a qualified engineer or specialist to determine the appropriate size and specifications for your needs.

Regular Maintenance

Perform regular inspections and maintenance to ensure the function is working optimally.

Compliance to Regulations

Adhere to local environmental regulations and guidelines regarding the installation, operation, and maintenance of bypass separators.

Don'ts:

Discharging Hazardous Substances

As with all the other Separators, it is not advisable to discharge hazardous substances, chemicals, or materials into the bypass separator. They can interfere with the treatment process, cause damage, and pose environmental risks.

Neglecting Maintenance

A big one for all separators, by neglecting regular maintenance it can lead to reduced effectiveness, equipment malfunction, and potential non-compliance with regulations.

With any separator there are many benefits, however the use of a bypass separator offers the following benefits:

- Environmental Protection

- Regulatory Compliance - reducing risk of penalties or legal issues.

- Cost Savings - minimising damage to drainage system, reducing maintenance costs and potential repairs.

- Enhanced Reputation - Demonstrates a commitment to environmental responsibilities.

(£1,441.20 inc VAT)

(£1,216.80 inc VAT)

(£2,710.80 inc VAT)

Summary

In summary, the main differences between these separators lie in their specific applications and the contaminants they are designed to capture and treat.

Full retention separators treat the entire volume of wastewater, forecourt separators focus on fuelling station pollutants, bypass separators capture various pollutants from different sources, and vehicle wash down separators are tailored for washing facility contaminants.

Each type of separator serves a specific purpose and contributes to effective wastewater treatment and environmental protection in their respective applications.

Read More from Tanks Direct

Fuel Tanks - Our range explained

What is Rainwater Harvesting?

Frequently Asked Questions

Sewage and Waste

Grease Traps

When and where would you require a grease trap?

If you have high levels of fats and grease you should use a grease trap. This would be fitted before discharging to the sewer.

Damage to sewer systems from FOGS can be extremely costly to local authorities and so there is much legislation surrounding best practices and correct disposal of fats, oils and grease, particularly for commercial food premises. If your property is connected to the mains drainage system and you’re serving hot food to the public or your staff, Building Regulations (document H, section 2.21) state you should have a grease trap or another effective means of grease removal fitted.

If you operate a commercial kitchen, such as a café, a pub, a takeaway service, a restaurant, a bakery or a staff canteen, a grease trap could help you to effectively manage your FOGS.

What is a grease trap?

It is estimated that nearly half a million tonnes of grease and fat enter the UK sewerage system each year, causing blockages and damage to pipes and wastewater equipment. Grease builds up inside pipes as it sticks to pipe walls and, if it enters a natural water course, fats, oils, grease and starch (FOGS) can seriously damage the environment. This damage is extremely costly to local authorities so proper management of FOGS is heavily enforced. Failure to effectively manage buildup could lead to heavy fines or even closure of commercial businesses.

Grease traps collect and reduce the number of FOGS entering the main sewers, helping to prevent drain blockages, bad smells and pest infestations. They can be located above or below ground, inside or outside your property, but positioned within the wastewater drain that connects your sinks and appliances to the sewer system. Fats and oils are much less dense than water, so they float to the top so, when wastewater enters a grease trap, it slows the water flow down significantly, separating solids to the bottom layer, wastewater in the middle and FOGS at the top. Wastewater is then allowed to flow into the sewer, while the FOGS are trapped.

How does a grease trap work?

Water and oil don’t mix. Animal fats and vegetable oils are much less dense than water, so they float to the top. In a grease trap, waste that flows through is slowed down and allowed a settlement period where solid waste sinks to the bottom and FOGS float to the top. A trap on the outlet prevents FOGS flowing through, permitting only the cleaner middle layer of wastewater to flow into the sewer system. Your grease trap needs to be properly maintained to ensure its continued effectiveness with regular cleaning required every two to four weeks by a licensed contractor.

Grease traps ensure grease and other build-up does not enter the main sewer system. Whether they’re attached to sinks, dishwashers or any other wastewater appliance that produce FOG, grease traps all perform the same basic function, with perhaps slightly different approaches. The size of the grease trap you’ll need will depend on the flow rate of the wastewater running through it — the higher the flow rate, the bigger the grease trap. At Tanks Direct we stock a wide range of grease traps in different size options to suit every flow rate.

What are the different types of grease trap?

Grease traps are a popular method of managing fats, oils and grease. At Tanks Direct we stock two types of grease traps for FOGS management — manual and automatic. Both do the same job of separating FOGS, solids and water within the tank, helping to prevent grease related issues. By slowing the flow of waste as it enters the grease trap and letting the wastewater cool, the elements naturally separate with solids sinking to the bottom, FOGS floating to the top and water remaining in the middle. What happens with each of these elements next is what differentiates a manual and automatic grease trap.

Manual grease traps are inexpensive and cheap to install. They simply contain and hold the FOGS until they are cleaned out. Automatic grease traps, also known as Automatic Grease Removal Units (or AGRUs), are more expensive than manual grease trap. However, automatic units systematically reheat and skim out the top layer of the tank where the FOGS sit, depositing it into a container where it can be disposed of easily. A separate filter catches any solid matter, which can be easily accessed and removed for disposal.

Login

Login

.png)